Filter technology for this industry:

Industry challenges

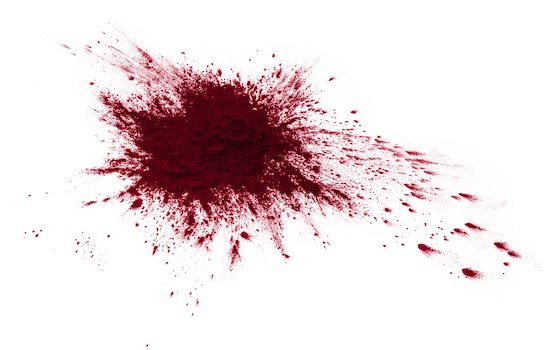

The blood powder industry is subject to stringent hygienic requirements. This makes state-of-the-art filtration solutions a must in their production processes.

Simatek filtration systems offer the industry optimised product recovery while helping control flammable emissions and unwanted dust deposits.

Our filters with direct product contact surface meet the EHEDG hygiene and food guidelines and can be used in a range of protection zones.

Industry requirements

- Implementation according to ATEX EN 14491 and VDI 3673 directives and the EHEDG and 3A hygiene standards

- Pressure shock resistance: from 0.64 to 2 bar

- Use of food-safe material for parts that come in contact with the product

- Reduction of harmful dust to correspond to the values of the TA air

- Efficient tool-free filter changes in the pure gas and raw gas area

- Manual and automatic setting of cleansing cycles

Our approach

We design and develop customised filtration solutions for the food industry –including filters made exclusively from food-safe material.

Our solutions are customised to meet the specific needs of our customers while being energy efficient, environment friendly and good value for money.

Our customers benefit from:

- Easy and efficient cleaning that meet high hygienic standards

- Optimised product recovery

- Improved processes and high productivity

- Assurance of sustained and improved final product quality

- Improved working conditions

- Low operating costs through reduced maintenance costs and minimum downtime

- Optimal use of resources